Packaged Drinking Water Plant Layout design is a very important step in setup of a plant. It not just gives a picture of how, what, where the elements are places, but also an effective tool to improve your overall plant efficiency.

Steps to Arrive at your Plant Layout

1. Mineral Water Plant Design and Plant Capacity

We have typically observed that this is the place where the entrepreneurs make maximum mistakes. Whenever, an idea of a Packaged Drinking Water Plant strikes to them; they hurriedly google it. Then Google, from it’s most intelligent sources puts results in front of them, which are dominantly the best which Google’s algorithm feels. They are usually the results (including the paid searches) from the mineral water Plants or the machinery supplier directories like the Indiamart, Alibaba etc. Their Job is to give the best to their advertisers, hence they prompt you with questions, the answers of which may be totally unknown to you. Then you just follow what the machinery supplier tells you (like 2000 LPH or 5000 LPH etc) which becomes YOUR plant capacity. Then the suppliers only decide your layout.

Is Google wrong ? Or Alibaba ? Or the Suppliers ? Or You ?

None of all actually. Nobody is wrong. But anything happens incorrect here does not hamper anyone else like you, as your money will be at stake. So it calls for you to actually know your plant capacity yourself.

Little reverse engineering here

You have to work little reverse. Its just like buying a Car. The first thing before you even go to a Car Showroom, You define the purpose for which you buy and then go to enquiry. Similarly, you need to know as to why you are setting up a Packaged Drinking Water Plant. Obviously, it’s to make some money. But more precisely, you need to know How will the money come to you. There will be something which you will sell, so what’s that ?

- Is it going to be 1 Ltr Bottles ?

- Or just 20 Ltr Jars ?

- Or a Combination of Jars & Bottles ?

- Just 1 Ltr Bottles , or also of 500 ml ?

- Or you are willing to introduce some odd volume size ?

- And how many bottles will you sell ? Daily, Monthly ? Annually ?

The Answers are tough, I know !

It’s not easy at all to find out answers to all these questions in advance , before starting a plant. But believe me , we have observed that 80% of entrepreneurs DO NOT KNOW this. And this can be the major reason of their failures.

How Can You Find this Out ?

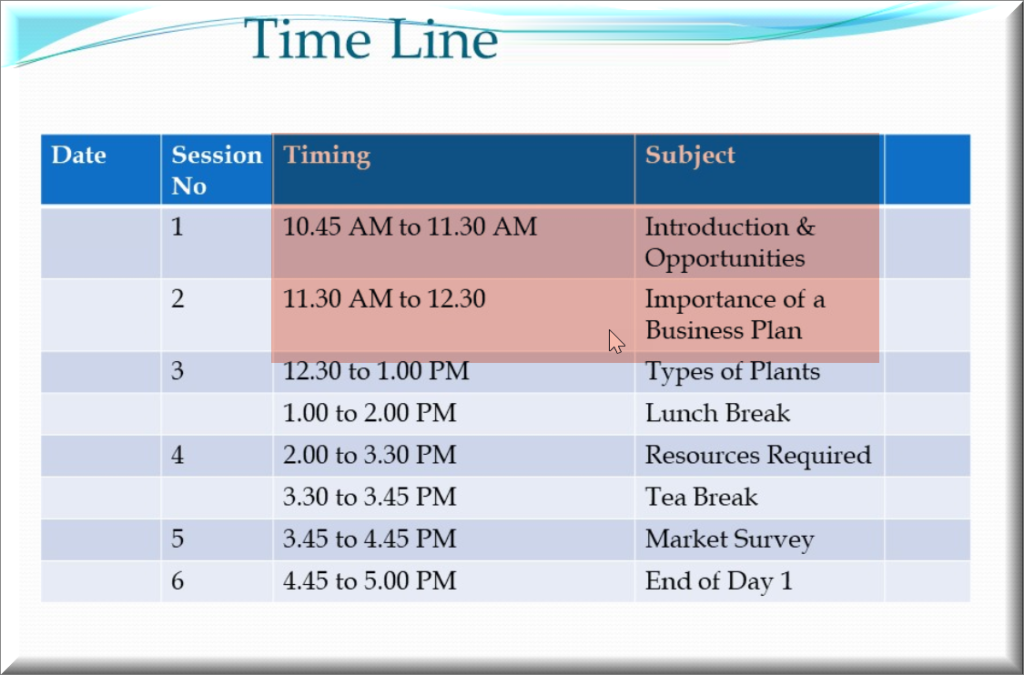

By carrying out a Market Survey , you can do that. It can be a Physical Survey or a Digital, or a combination. You can hire some agency or can do with some guerrilla technique. We give some special tips to the participants on these during the Idea to Actualization Sessions .

The survey should produce you figures on how much per variation you will produce per day. This will be your production plan. From this you will exactly know the plant capacity.

2. A little reverse-work here !

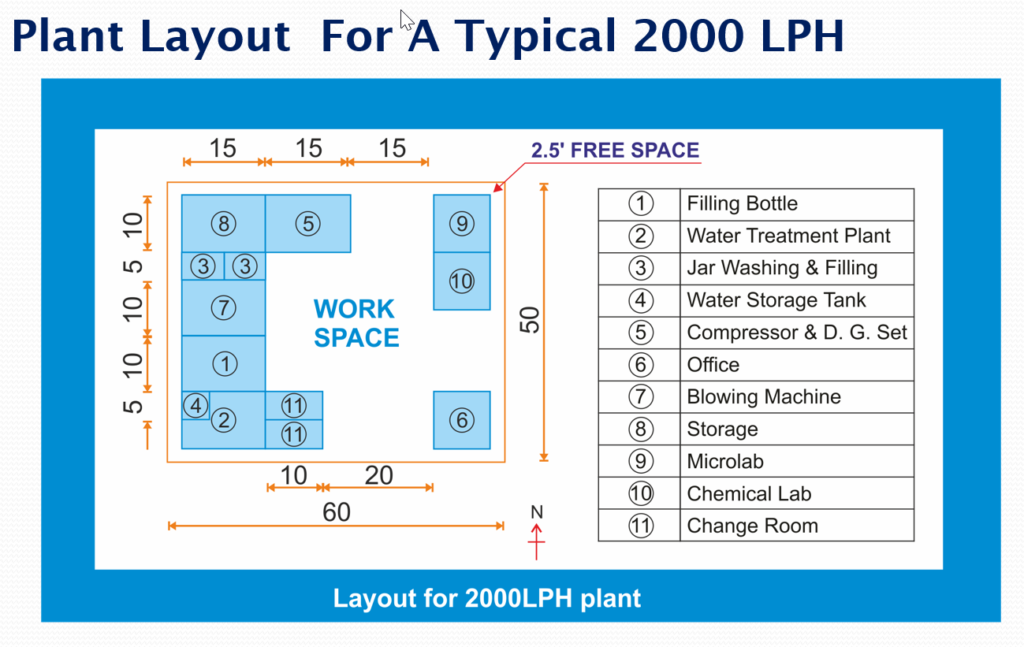

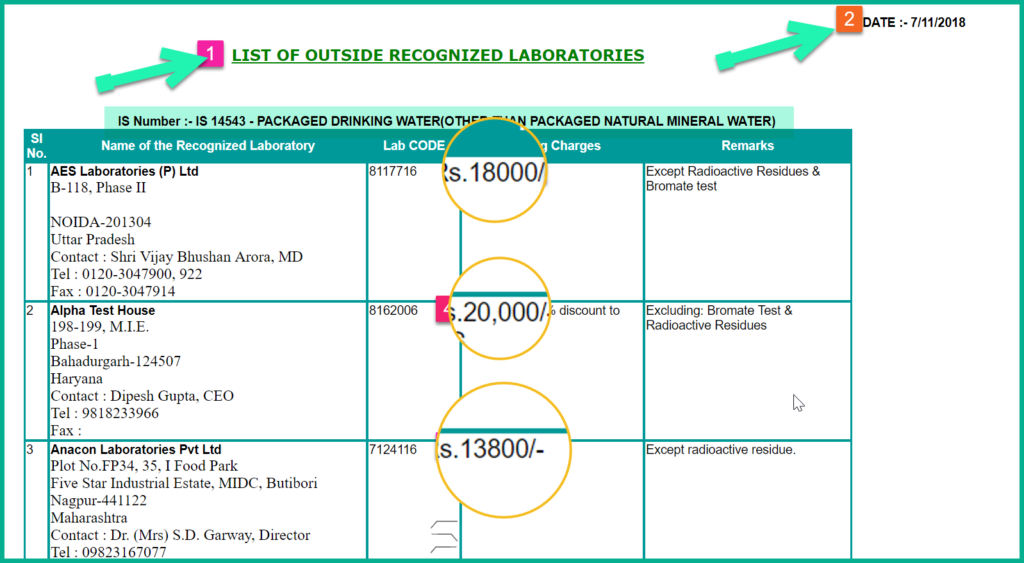

Once you know the Plant Capacity, get details of the machinery & dimensions as well. This is the next step to design your Packaged Drinking Water Plant Layout. Also be aware of the rules of the B.I.S. on space allocations. (We share you details of this during our training sessions by which you understand how much space the machinery demands).

3. Design Man-Material Movement

Placing the machinery at proper locations demands exact know-how of the process flow. According to the process, design your plant in such a way that your workers need the least to and fro movement; so that they work with good energy levels. You also need to have a look at the BIS norms, which might be the guiding stones to maintain proper hygiene. However, most entrepreneurs do not emphasize this point of considering the human fatigue while designing their Packaged Drinking Water Plant Layout.

4. Mineral Water Machinery Placement :The last step

Once you allocate proper place for the machinery & equipment, your Plant Layout will be ready.

Learn the techniques first hand ..

Join our Training Courses, and design your Packaged Drinking Water Plant in a professional manner. Just pick-up the suitable session from the list provided on the Training Schedule Page and attend one. There are 100s of entrepreneurs attended this & almost 30% of them hace already started their businesses.

If you attend our

If you attend our