Mineral Water Plant Cost : How can one calculate this

Mineral Water Plant Cost is unarguably the first consideration which comes to the minds of entrepreneurs , who wish to setup their plants. Though an entrepreneur is driven by the sense of Opportunity in this field, his further decision starts or stops here.

Is Mineral Water Plant Cost Calculation Important ?

Yes. The First Reason :

Most of the People ask us this question

“What is Mineral Water Plant Cost” still remains the most asked question to us. Almost every businessman, whether he wishes to run a local jar business, or wants to start a Multi state level franchise business; he definitely asks this question. Furthermore, we too, feel that it is the fundamental consideration, even before the profitability. Mineral Water Plant Business is becoming more and more competitive; hence, knowing & operating on cost measures is one thing where you may outscore others in the business. Making profits is the challenge, and the reason to many closures, is not getting less business, but getting less profits, sometimes negative profits.

Cost Control is the 1st thing, and to control cost, one should be aware of them.

Reason No.2 :

Knowing our “OK” Investment Zone

The “OK” Investment Zone for every entrepreneur is different. If you are a 1st generation entrepreneur, you may consider to go slow and steady, going from small to middle, and then large. On the contrary, if you belong to an existing business family, you might think of starting big from the beginning. In both of these cases, the Investment is different from each other. Hence the Investment Cap as well. For someone , 5 Crores will look as a massive investment, to other even 50 Lakhs, or the matter of fact, even 5 lakhs also may be challenging for someone.

But, the business has its attributes. Every business is created for profits. And to let it run in profits, it has some certain costs. Similarly, Mineral Water Business also has some costs with relation to the Business Model you select. This Cost, whether it is comfortable to you or not, will solely depend upon where you come from. And what is your acceptable investment. This is what we mean by the “OK” zone.

Overall, it will be necessary to see whether investing in a Mineral Water Business be worthwhile or not.

Reason No. 3 :

Just Machinery Cost is not the Mineral Water Plant Cost

Many times, participants from our Live Training Sessions, get frustrated after a special session we conduct on Comparison of Various Plant Models. In this session, we compare 2000 LPH, 5000 LPH & just the jars Model Head to Head with the complete R.O.I. based calculations. There the less informed entrepreneurs get surprised by the amount of money involved in this business.

We have observed that if you are an entrepreneur, you will first Google on terms like “Mineral Water Plant Cost”. Or you may visit certain sites like the Indiamart or Trade India or Alibaba. These are the Directory Sites for Industries, the aggregation of the businesses in various industries. A data collection of the manufacturers or the suppliers dealing in that.

At the beginning, an entrepreneur like you contact a few of them and get price quotes from some of those. Typically for Mineral Water Plant, you will see that all of them are Machinery Suppliers. They may claim and they might be supplying all the machinery as well; they don’t give you the actual total project cost. What they give you is the Machinery Cost. Most of them.

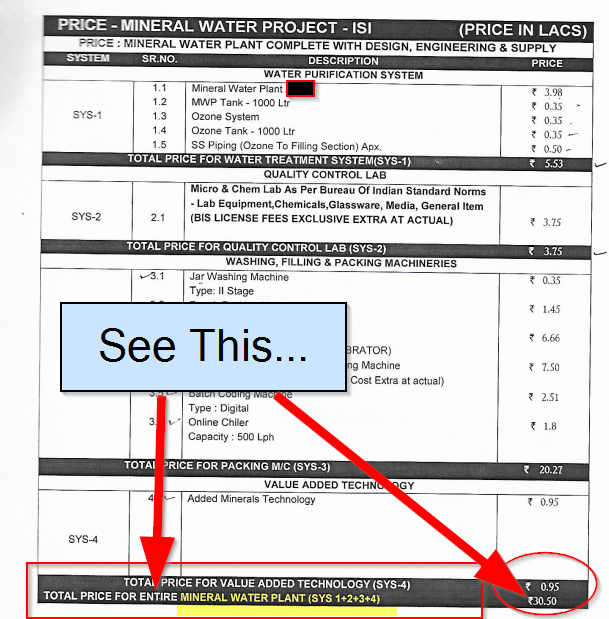

For Example, study the image & table below which tells you what might be missing out from the various quotations you receive from mineral water plant suppliers :-

Sample 1000 LPH Mineral Water Plant Cost Calculation

| Cost Component Head | Cost Component | Component Available or Missing | Appx. Price (Lakhs) | Remarks |

|---|---|---|---|---|

| Machinery | Water Treatment Plant with Added Minerals Section | Yes | 6.50 | |

| Q.C. Lab as per the BIS | Yes | 3.75 | ||

| Packaging & Bottling Machinery | Yes | 21.00 | ||

| Utilities | Electrical Transformer, Generator etc | MISSING | TBC | To Be Calculated |

| Cooling Towers, Compressor , Air Conditioners and Other Utilities | MISSING | TBC | To Be Calculated |

|

| Building & Construction | Shed, Fencing, Internal Furniture as per ISI | MISSING | TBC | To Be Calculated |

| Misc. Work | Civil, Plumbing, Internal Electrification, Softwares, Licenses, Manpower etc. | MISSING | TBC | To Be Calculated |

Details About Each of the Cost Components

There are major & minor cost components. Calculation of detailed cost components is the job of a Chartered Accountant. However, we have created a separate page for the major Mineral Water Cost Components.

# There may be addition/deletion in the cost compenents. For example, there would an inclusion of Plastic Recycling Cost in each of the producer’s costing due to EPR

However, we strongly suggest you to attend one of our Live Mineral Water Plant Trainings. We list down this each item & get you to the actual cost through dummy case study.

Alternate Way is to get a consultancy from us in which we visit your proposed plant, help you create the layout, create the financials prior to you going to the CA, and also be with you till your proposal get submitted to bankers/investors.

Contact us for consultancy

Reason No.4 :

You need to also consider the other costs

The other costs include land and building, other utilities cost, operational cost, cost of capital and other costs. Under the session we mentioned above, we lay down a special focus on this and train you on the aspects of drilling down to your exact initial investment even before you go to your chartered accountant who prepares your project report.

Reason No.5 :

Cost vs Investment

Generally, entrepreneurs ask us questions like “how much mineral water plant cost for 20 Ltr Jar Plant” or “How much Money is required for a 1 Ltr Bottle Plant“. By this means the initial investment required. He doesn’t much bother about other things. And this is okay when your dream is vague and not properly defined.

(Note :- There is a Special separate article on calculating 20 Ltr Jar Mineral Water Plant Cost)

But, if you wish to go further, you require further information on the exact cost of the whole enterprise. Now, let divide this into 2 separate phrases :

- Mineral Water Plant Cost and

- Mineral Water Plant Investment.

Mineral Water Plant costs are the various expenses you shall be making from time to time to keep the entreprise running

Mineral Water Plant Investment is the actual Money required to meet the costs from Time to Time.

So, how do I arrive at Mineral Water Plant Investment ?

First of all, please understand, that there is no fixed cost for a Mineral Water Plant. It differs from every entrepreneur.With the selection of his own Product Mix. The Product Mix and daily production you have planned in mind, will give you the various costs involved.

Once this is done, you can present the statements to the Chartered Accountant, who will prepare the projections and guide you on how much will be your R.O.I. As mentioned, in our Live Training, we do conduct the processes to decide your product mix and also detailed training on considering every cost component. So that, you arrive at your Investment to make the venture profitable.

Steps to get the exact Mineral Water Plant Cost & Investment :-

- Carry on a Local Market Survey (Or International depends upon your vision). Market Survey is a critical thing. You can do it with your own way; or can get it done from Expert Practitioners in the field. It again depends upon what is your lookout.

- Decide What you will be producing and How much, this is your product mix.This can be had from the Market Survey. We do conduct a session on this during our Live Training.

- Present the calculation to the machinery vendors, get their quotes. Once your Product Mix is ready, you can reverse calculate the machinery specifications from that. We conduct an activity exercise during our training to do this yourself.

- Decide the Shed Size, Outer Area you will require, to get the cost of construction. Once you receive machinery dimensions; you can arrive at floor space (With reference to the B.I.S. norms on this).

- Decide other resources cost such as Electricity, Water and add to the cost.

- Total them out, this is your Mineral Water Plant Cost, the initial project cost.

Note :-

(a) Actually, the cost should include both :- The Capital Cost & Operational Cost. The above example only tells you Initial Money or Investment required for Starting the Mineral Water Plant.

(b) In our Live training, we conduct special sessions on all these aspects. Check out reviews and also the next schedule ! Or Contact Us to Know More about the next training. (It is recommended to please read out the FAQ prior to contacting us.

(c) Kindly sign up to our Newsletter to be kept informed about our further trainings and also getting industry updates.

99 replies on “Mineral Water Plant Cost”

dear, hope r well, we are interested the new mineral water plant build,please give instruction & guideline whole project build from beginning ;

machinery cost & others cost mentioned clearly ; thanks

vision software.inc

bangladesh

I want to start new factory of mineral water with packing of 1ltr bottle. So please detail us the total investment to start factory and area required. and Also give us the ratio of profit we can earn.

Dear Mr. Solanki,

It’s great to know that you are willing to start new factory of mineral water with packing of 1 ltr bottle.To detail out the various things you expressed, we suggest you to attend our Training Scheduled on 29th & 30th September 2018. It will be at Pune. You can also check detailed reviews on the Past trainings held :-

Dear Mobin Uddin,

Attend Our Live Training at Pune, India. Also check Reviews

Hi sir,

we are planning to start miniral water plant for our village purpose, not for business, can you please provide the estimation for 500 Leters per hour. It should be purifier the florin also.

Thank you very much…

Sir, I have sent you an email where you can send me clarification on many points. However, in our Mineral Water Training Sessions, we do have a session on Community Water Sessions.

Hi,

We want to start mineral water plant, required your guidance and expertise.

Regards

Amardeep Khobragade

Dear Amardeep,

Thanks for writing. We shall definitely guide you; meanwhile I suggest you attend our Live Training where all your initial queries will get completely cleared. Call or Whatsapp 9822478111 for details.

Dear Sir , I want to open new water plant.Please guide me.

Dear Mr. Mishra,

Thanks for posting comment.I would strongly suggest you to attend our Live training, where you will get step by step guidance.

Sir iwant fully automatic mineral water plant plz give me complet unit cost thnx

how to start mineral water plant project and what will be the cost in ASSAM

Dear Sir,

Would like to start a mineral water manufacturing/packaging business as a outsourced entity for other established brands like Bisleri, Aqafina, Kinley, etc. Would appreciate your guidance as how to go about the same and whom to approach in this regard.

thanks..!!

Hey Hii !

I’m From Kanpur

I want to know that it is neccassary to take ISI mark from BIS office for packing of Pouch and Bottles.

Good afternoon sir, i want to start new water plant for small scale business soo I need your your suggestions and required information thanking you sir…

Sir i want to open new water plant pls guide me

Dear Ramu, you can attend Live Training we conduct. This will provide you total information.

Dear Nitin Kumar,

Small is really a relative term. However, smallest plant will require 25-30 lakhs to setup. Better attend our Live Training for ideas.

Dear Sumit,

Yes, it is mandatory.

Actually, you will need to have look at their sites for this purpose. However, we would suggest you establish your own brand.

Dear Sharif, cost is almost the same everywhere in India, however you can attend Live Training to know the exact steps to start a mineral water plant.

This depends upon what is the plant capacity. Please specify that.

Sir I want to open new minaral mini water plant how much cost please and guide me please sir

Dear Laxman, “Mini” is how much ? According to our experience the lowest plant in this will require 30 Lakhs to setup, which has a jar plant (ISI Appoved).

Hi,

I want to start a mineral water plant.im having area of 50sft area…how can i staet this and can i get ant financial assistance from any banks or govt on this

Dear Janardan, You require at least 2000 sqft area to start the minimum capacity plant.Within the area you have suggested, you can setup a small Water ATM machine, install that at a busy junction & make money by selling the water at a price.

Dear Sir/ Madam,

I am George Kingsley and I am trying to set up a small mineral water factory, using sachet and not bottle, I am from Liberia in west africa, Please I need the drawing of how the factory can be with names of Item needed.

Just like if one wants to build one need the plan of the structure. I will appreciate it if my question is address.

Dear Sir,

I think what you may be looking for is a Plant Layout. Though every plant has its own layout; we train our participants at the training on how to design the said. I understand you are not from India, however, we can help you out with full setup of the plant with machinery & installation too !

Hi

We have a large area of land in Uttarakhand and a small river which flows through it. The water of the river is natural mineral water for which we want to put a plant to have it bottled.We live in Lucknow,Up.Can u guide how to proceed.

Hello there!

I would like to know the details about the live training which is the date,venue,charges etc…can I get a replay from you through email ?

Dear Shveta,

Very many thanks to give a detailed Idea.The source of the river water should be the first source, then it can be called as Natural Mineral Water. The plant is similar for this like the Packaged Drinking Water. The treatment portion varies a little. More technical things can be discussed about this during 1-2-1 meeting. You can attend one of the training Sessions we conduct. Since you are from Lucknow, you can attend the Mineral Water Plant Training Session coming up at Delhi on 5th May 2019. We also have a special post for this :-How Much Raw Water is Required for a Mineral Water Plant Daily

Dear Zainul,

You can find the training schedule :- https://mineralwaterprojectinformation.org/mineral-water-plant-training-history/, We shall email you the details sir.

I want to start a mineral water plant at least 2000 sqft area.We have much pure natural well water facility.Please give me the instructions & guideline related with the project from beginning,machinery cost and other cost mentioned clearly,Bank Loan Facilities and govt help related with subsidy,Mineral water plant training details in nearest cities and its fee.I want to use the market opportunities in Tamil Nadu and Karnataka States….

Dear Jinto,

Greetings.

We already give you the guideline to start a Packaged Drinking Water Plant through the training we have created for this purpose.I request you to kindly check the sessions at : Training Schedule

Many many yhanks , for your information. I am interested in opening a mineral water plant. Please givr me full information for this project and advise for the same.

Dear Manisha,

We are happy that the information is finally helping you.Full information about the project is shared during our training “Idea to Actualization” held at regular intervals.It covers almost every aspect for a new aspirant willing to start an enterprise in this space.Till date we have conducted 38 trainings, more than 500 entrepreneurs & almost 30% of those have started some business in this line. We suggest you to kindly check the training schedule as well.

I want to start 20 Ltd and 1 lt bottle mineral water plan . I have for a slot size of 400 sft. . What’s the totally investment cost for the project in Bangalore city. Kindly let me know the details project want to set up at the earliest. Thank you

Dear Mr. Reddy,

I appreciate your sincere interest in the business; however,if the Plot Size you mentioned (400sft), if that is right, then it’s small for a plant you are looking to setup. The total investment for a typical 2000 LPH Plant (which is viable) is 75-8- Lakhs & Land required is 5000 sqft. Attend a Live Training where we train you on how you can exactly calculate your total plant investment in details.

is it possible to package purified hard water from well and will the business be feasible

Yes, It is possible to treat water from well & packaged that into bottles. It has a process. This will be packaged drinking water business.

Hello Team,

I want to start water purified plant 1 litre bottle and Jar in Dapoli (Ratnagiri).

Could you please let me know the overall cost for plant.

Dear Swapnil,

We shall be very happy to help you out with this. I suggest you to let us have certain details :- https://forms.aweber.com/form/87/931268087.htm

hi sir , i want to open a mineral water plant fully automatic 200ml to 20ltr jar , so guide me sir which document require and where i can apply for loan

I am from kerala where we are abundant with rain water for a whole 4 months,every day there will be around 500 liters of rain water falling to our roof and end up in sea through rivers and canals ,what we are planning is getting a rain harvest system to atlest a 250 houses collecting it to a huge plant working on a public private partnership processing them and exporting to uae or to north indian states. Please tell me an approximate cost of initial and running cost. IN our project every householder will be a share holder and we are ready to pay 25 paise per liter for each family.

Dear Kamalesh Agarwala,

We have created full fledged trainings for this purpose. You can attend Live Training at various locations in India. If not possible, Buy a Home Study Module

Sir,

Rain Water Harvesting is not our cup of tea. However, if you harvest the same, and want further filteration & community water syatem through a Water ATM, we can supply that.

Tell me the challanges in the market regarding the cost and quality due to compition of brands products

Dear Manoj, Attend one of our Trainings

Hello Sir,

I want to start a mineral water plant. Please give me the instruction & guidelines related to the project from the beginning, machinery cost and other costs mentioned clearly. I want to use the market opportunity in Maharashtra, Pune, Chakan city.

Dear Mr Adsul, You can join our 2 days training upcoming. It will give you complete information. For details, you can also use Whatsapp

i am interested in putting this water mineral plant which place we can contract in vaishali ghaziabad what are the machinery needed for this plant and how much space we needed what is the aforable cost for this plant i am staying in vaishali ghaziabad u.p. and let me know the cheap plant easy to handle started my water plant with quick results

Want to start new factory of mineral water packing of 1ltr.bottle.so plz detail us the total investment to start.

Total Investment depends upon size of plant. However, a plant of size 2000 LPH will cost appx 70-75 lakhs. You may attend a training to know more

You need to define the requirements properly. Attend a training.

There is open drainage near my plot ..wher I want to start Mineral water plant.pls tell me according to isi and bis ,how distance to be kept between plot and open drainage.

Near meaning how much distance ? And if it can be resolved with Pollution Board, need to check it.

I like to know how to start a mineral water plant

Ok.We conduct training for this aspect.

Please let me know details about 4000LPH BOTTLING PLANT IN WEST BENGAL.

Sorry for a belated reply. What exact details you need ? Meanwhile, you can sign up for our newsletter to have free updates

hello sir,

i want to open mineral water plant 500 lt per hour how much it cost and which machinery i need to setup and how much labour i need total expenses pls tell me i have mention my email id and my contact number is 7737272336 pls call after 6 at evening.

500 Ltrs per hour is small investment. All of your answers can be had at the Training

Hello sir , we are looking for partnership and help for a ready to start mineral water plant in Assam . land and construction of the water plant is ready (3000 sq ft) , 70 percent of machinery (brand new) is being purchased .More than 80 percent of the necessary legal works is also completed . Interested parties contact or wassup – 6900888274

Hi sir I am from nepal and I want start a small factory of mineral water in a ruler area so could you please guide me about the process and total expenditure in this factory?is it profitable business or not sir?

You may attend our Trainings to learn this.

I want start new mineral water plant let me know how much cost only purify machine

Dear Gaurav,

It seems from you comment that you require the price of the Water Treatment Equipment. First, you will get that from sites like Indiamart (from Suppliers) & second : You need to mention the capacity of the same.

sir,

I have been planning for setting up of 1000 LPH automatic 1 litre Mineral water bottling and 20 liter Jar filling Plant in Bingaiagaon district in Assam. I have 6000 Sqft land area adjacant to the National Highway and I have already taken FSSAI licence for this. Now I want to know the approximate investment cost for all component, to start the bussiness.

i want make a research project on PROCESS COSTING OF MINERAL WATER PLANTS

can you please help me or guide me via provide some technique knowledge

I have a commercial land at khuda road , Bhubaneswar where I want to develop a package drinking water factory with a minimum production capacity will be 72,000 bottles of 1 lt per day. How to calculate the total cost involve including electricity and all others.

Replied to your email ID

Write to me separately on contact@joywebservices.com

Attend Training

We have brand new 2000 lph mineral water plant machinery( RO plant ,FILLING MACHINE , SS TANK, JAR WASHING WITH FILLING LINE , BOTTLE MOLD , IRON REMOVAL PLANT . available (Assam) interested parties , looking for buyer . Interested parties wassup 6900888274

We have brand new mineral water plant machinery ( RO PLANT , FILLING MACHINE , SS TANK , JAR WASHING WITH FILLING LINE , BOTTLE MOLD , IRON REMOVAL PLANT . LOOKING FOR GENUINE BUYER , INTERESTED PARTIES MAY CALL OR WASSUP 6900888274

I have posted this on site. If the buyers need technical consultation, can contact us

Dear sir we want to start mineral water plant in 1litre and 1/2 litre near to nagpur

Total plant cost

Total Plant Cost, if you saw on the post has several components, and we offer full detailed training on this. Attend the next one. You may subscribe to Newsletter Email Alerts as well.

New drinking water plant 500ml,1000ml,etc. Needed plz call me.9763999832

Hello Mr. Bagwan,

We have tried to contact you but your number was busy. Have you decided the capacity of the plant?? We provide training and consultancy service for the mineral water plant entrepreneurs. Please feel free to connect with us on mineralwaterpune@gmail.com or 9822478111

I want to start business water bottles nd water pouches

Looking to setup a fully automatic mineral water plant with 6000 LPH capacity. Need more information..please call back @9535243243

Hi,

I stay in Mumbai. One of my friend is interested in starting a mineral water plant. right now is the budget in setting up the entire plant. Can you help us by sending us the quotations.

Our requiremets is for roughly around 5000 liters plant.

Hello,

Greetings!! Please check your Email, details are sent to you. Please feel free to connect with us on mineralwaterpune@gmail.com or 9822478111.

Thanks and Regards

Hello,

Greetings!! Please check your Email, details are sent to you. Please feel free to connect with us on mineralwaterpune@gmail.com or 9822478111.

Thanks and Regards

Hello,

Greetings!! Please check your Email, details are sent to you. Please feel free to connect with us on mineralwaterpune@gmail.com or 9822478111.

Thanks and Regards

Hello Dear!

In hopes of good health and life for you. I want to start a factory of mineral water in Termez and Tashkent Uzbekistan, so I need the total proposal of investment and implementation plane with its budget calculation. so I want to know how can you help us from the beginning of this project to the end.

sincerely ( Sadat )

Dear Sadat, you can setup an appointment here

I wanna start my manufacturing plant of mineral water, so please help me with you guidance of cost of this project,investment,profit etc.

Please response as soon as possible

Want to installation of water production plant.

You can avail my consultation, for which we charge Rs. 5000 / USD 100 in which I will listen to your probable plan, give you my suggestions and will suggest you the best possible option according to me. We can have 3 sets of communications in this :

1. First Pre-call email

2. The Call on Zoom ( 15 – 20 minutes )

3. First Review & suggestions by us through Email

4. Explainer Zoom Call 15-20 Minutes if needed

5. One more email Review.

The tenure for this will be 1 Month.

You can avail my consultation, for which we charge Rs. 5000 / USD 100 in which I will listen to your probable plan, give you my suggestions and will suggest you the best possible option according to me. We can have 3 sets of communications in this :

1. First Pre-call email

2. The Call on Zoom ( 15 – 20 minutes )

3. First Review & suggestions by us through Email

4. Explainer Zoom Call 15-20 Minutes if needed

5. One more email Review.

The tenure for this will be 1 Month.

We want to set up a mineral water plant in Khunti, Jharkhand for commercial purposes.

My Wattsapp number is 9031781093.

Please guide us.

We offer paid consultancy now. Please whatsapp on 9822478111 if interested

Please contact me on 7710014844

Request you to drop a message sir

Was interest in setting mineral plant in Shillong, Meghalaya, north east

Chargeable service. Kindly send email on mineralwaterpune@gmail.com